Recycling is an effective and environmentally friendly treatment method. Therefore, VINAUSEN constantly researches to come up with recycling treatment plans to thoroughly recover waste that can still be recycled.

1. Recycle waste oil and lubricants

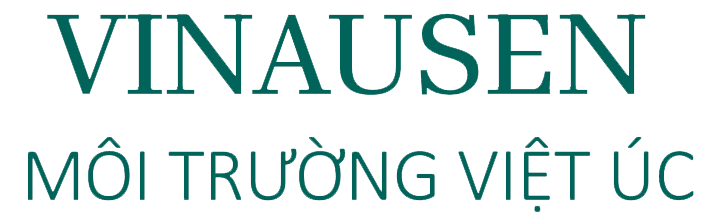

Waste lubricant mixed with water is pumped into the phase separation tank (1) to separate the phases into oil phase and water phase. Oil from the phase separation tank is led through the mixing tank, where the condensation product is injected with the appropriate dosage and stirred for 30 - 60 minutes (speed 20 rpm). After stirring, the oil mixture in the Mixing Tank is pumped through the Phase Separation Tank (2) to separate oil and residue. The oil above is recovered and reused, the residue below is burned and destroyed in a 2-level furnace with an exhaust gas treatment system.

2. Recycle waste solvents

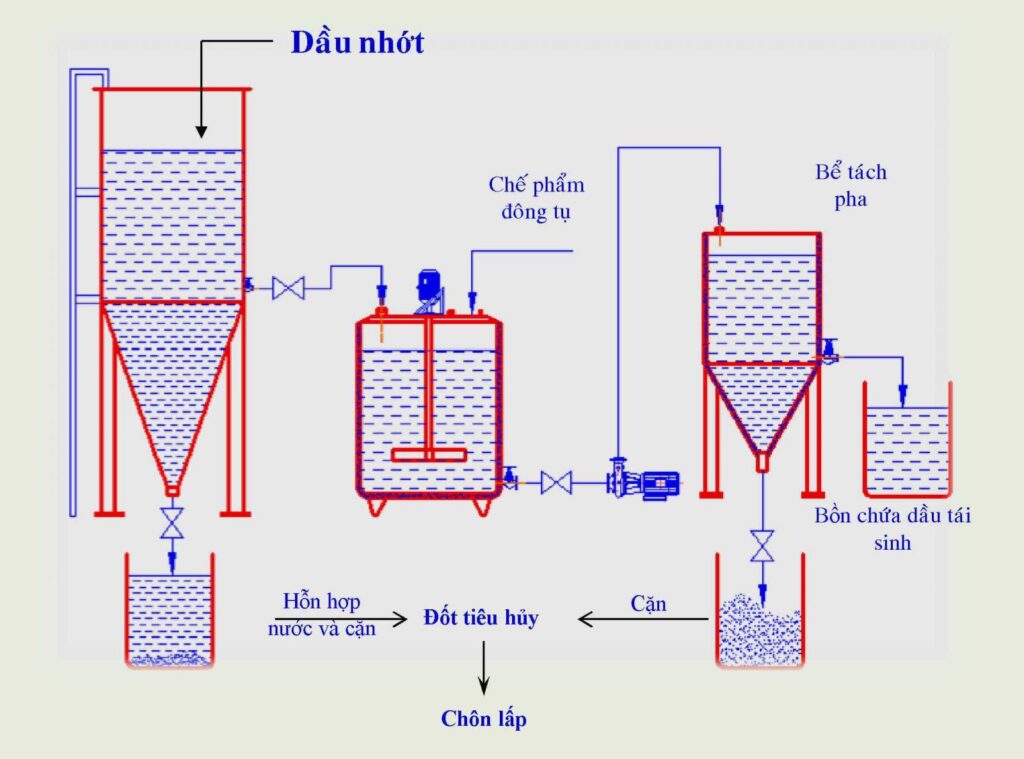

Solvents of all kinds from the tank (1) are pumped into the heating pot (2) to a certain volume. At the heating pot, the resistance system heats the mixture to the evaporation temperature (40 - 200oC). The solvent vapor is directed into the condenser (4), where cold water is used to condense the solvent. The solvent mixture after distillation is passed through the separator (5) for separation. The impure solvent part is circulated (7) back to the distillation column, the pure solvent part is recovered and reused. The residue is periodically blown down and treated by combustion in a 2-stage incinerator with a gas treatment system.

3. Recycle drums and containers

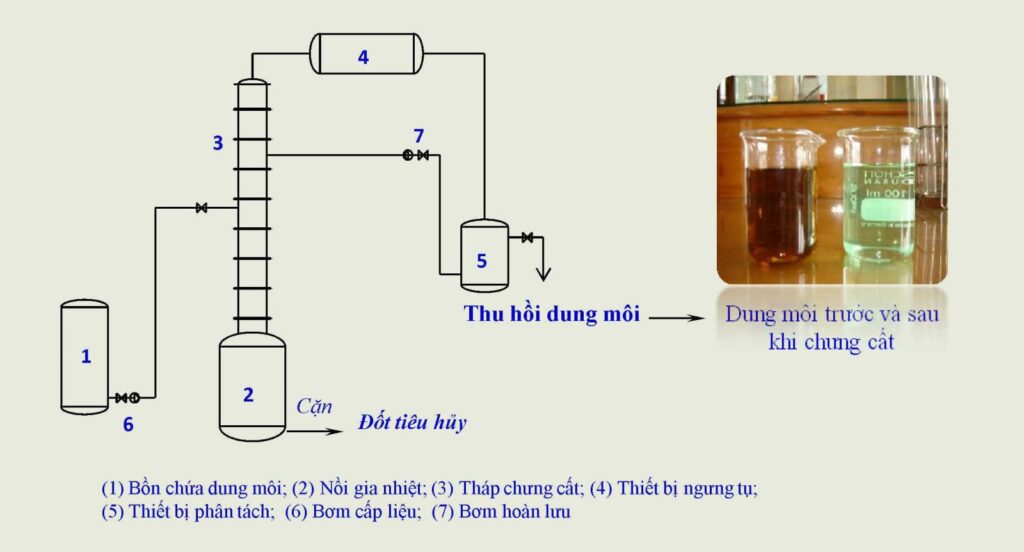

Drums/containers containing chemicals of all kinds are placed in the soaking tank for the necessary time to remove part of the adhesive while softening other hard adhesives. The tank is then rinsed in the pressure spray system with detergent. After washing with detergent, the tank is rinsed with clean water in the pressure washing system until completely clean. Clean barrels are reused to store lubricants or some industrial chemicals. Wastewater from the rinsing system is treated at VINAUSEN's wastewater treatment system before being discharged into the Industrial Park's treatment system. Sediment from the rinsing process is burned in a 2-level incinerator, the ash after burning is solidified and buried safely.

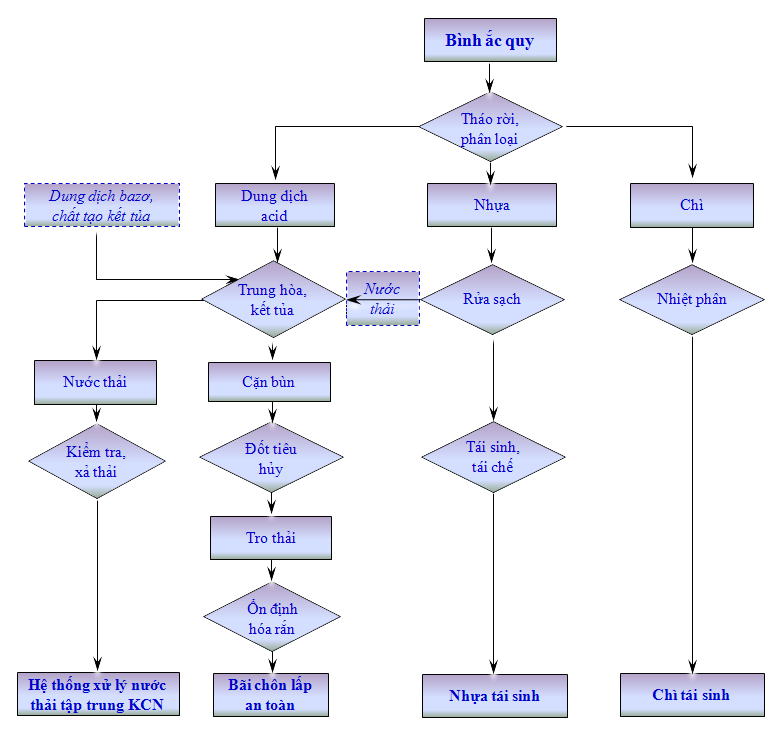

4. Recycle batteries

The battery is disassembled and separated into lead, plastic and acid solution. Lead is melted to be regenerated in the lead recycling system. Plastic is washed in the rinsing system before being ground into raw materials for plastic production. The solution in the battery and the water from the plastic washing process are put into the tank. Here, NaOH solution will be added to adjust the pH to ~ 6 - 7.5 and the precipitate will be solidified - buried. After neutralization, the solution will be tested and discharged into the general drainage system of the Industrial Park.

The residue from the entire treatment process is burned in a 2-stage incinerator, the recovered ash is solidified and safely buried.

5. Recycle electronic waste, non-ferrous metals and others

In addition to the above types of scrap, VINAUSEN also recycles electronic waste, rubber, plastic, paper, iron and steel and other types of scrap.