Process Description

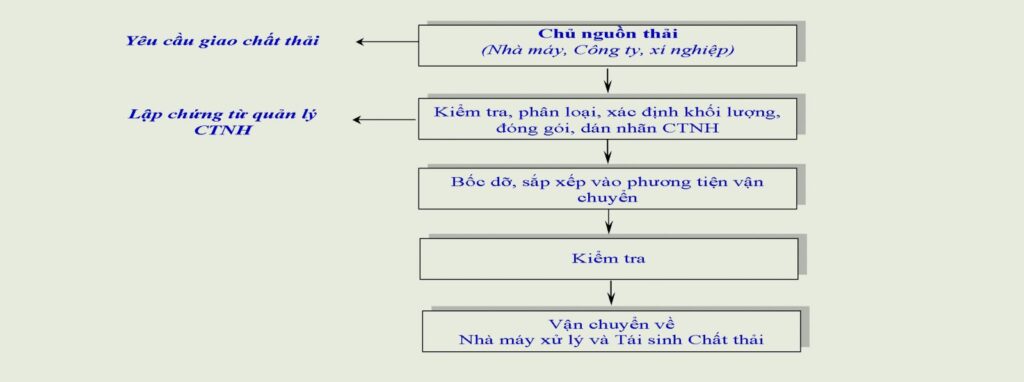

After the customer (Waste Source Owner) contacts to request collection and transportation of waste, VINAUSEN staff and transportation vehicles will go to the Waste Source Owner's location to receive the waste. Here, VINAUSEN staff check the current status of packaging, labeling and storage of waste according to regulations on hazardous waste management.

Depending on the composition, properties and characteristics, waste is stored in different equipment to ensure safe transportation and avoid waste spillage and leakage:

– Types of solid waste (such as rags, gloves stained with lubricants, chemicals, solvents, packaging stained with chemicals of all kinds, powdered waste, chipboard edges, waste electronic circuit boards, etc.) will be stored in PE bags, fabric bags or containers.

– Lubricants, solvents, and chemicals will be stored in plastic or iron containers.

– All types of wastewater and liquid sludge are stored in tanks and transported by tank trucks.

After checking to determine that the waste has been classified and stored according to regulations, the two sides proceed to weigh, measure and determine the quantity and load and unload onto the transport vehicle. At the same time, the Waste Source Owner prepares a Hazardous Waste Document according to the prescribed form of the Ministry of Natural Resources and Environment. When the loading and unloading of waste is completed, the delivery staff checks again to ensure the arrangement of waste on the vehicle is in accordance with safety regulations before allowing the vehicle to transport the waste to VINAUSEN's factory in accordance with the regulations. prescribed route.

The staff receiving waste is regularly trained and trained in emergency response measures. In addition, the company also regularly maintains transportation vehicles, equipment, protective gear, etc. to always ensure safe collection and transportation.

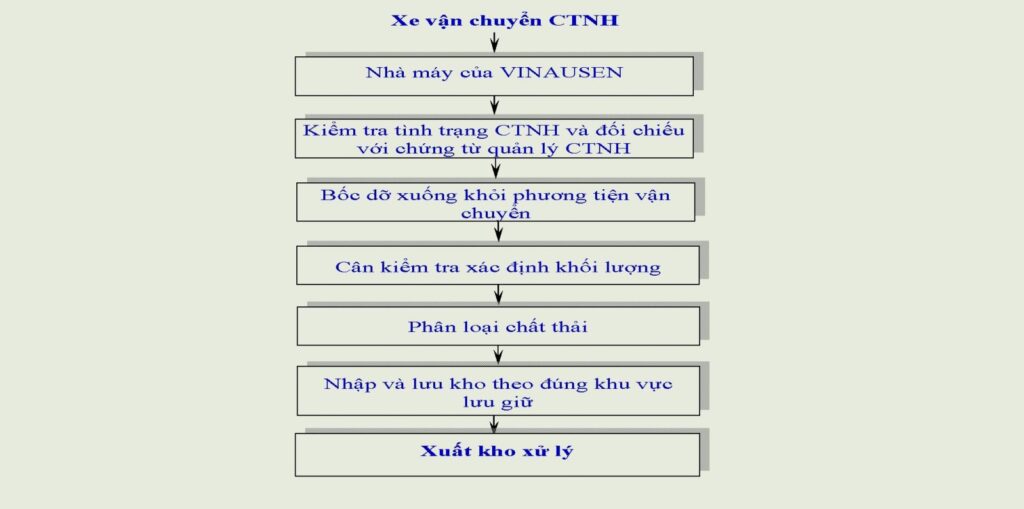

After being transported to the factory, waste is inspected and unloaded onto the transport vehicle according to the waste storage process as follows.

Process Description

When the waste transport vehicle arrives at the factory, it is inspected to ensure that during the transportation process, there is no disturbance between types of waste.

If the waste is not disturbed, the Classification Team will compare it with the HW Management Document to determine the type of waste and unload it onto the vehicle. If the waste has been disturbed, the Classification Team conducts preliminary classification based on the Hazardous Waste Management Document immediately upon loading and unloading the waste from the vehicle and assigns the Warehouse Team to weigh and measure to determine the quantity.

After obtaining preliminary data, the Classification Team conducts detailed classification and packaging of waste according to VINAUSEN's specifications to facilitate treatment. Waste is classified into groups corresponding to the treatment plan of each type of waste: incineration treatment, solidification treatment, recycling treatment...

After classification, waste will be imported and stored in the prescribed area to wait for release and treatment according to the given treatment plan.

II. TREATMENT AND DISPOSAL OF WASTE

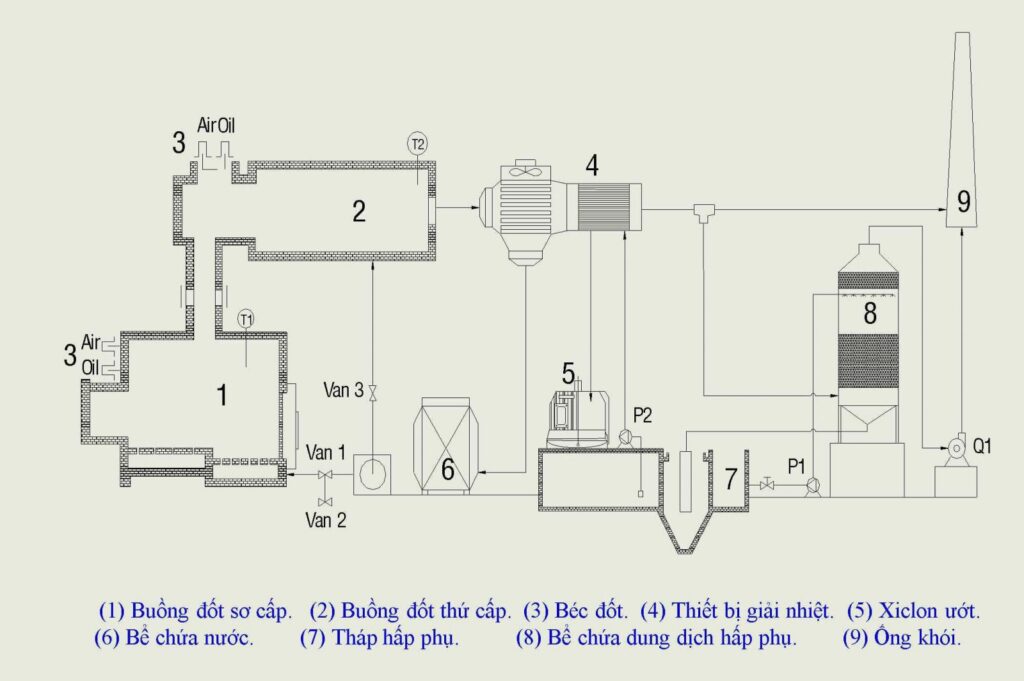

Technology description

The types of waste that need to be burned will be put into the incinerator in batches, the fuel used for burning is DO oil. At the primary incinerator, fuel will be sprayed into the incinerator through the burner to burn waste and always maintain the temperature in the incinerator at (550 - 6500C).

Gas produced after combustion from the primary incinerator will be directed through the secondary incinerator to burn the remaining components in the exhaust gas at a higher temperature (about 1000 - 1,2000C). Similar to the primary furnace, in the secondary furnace DO oil fuel is also injected to maintain the temperature in the furnace. Gas generated from the waste incinerator will be directed through a heat exchanger to reduce the temperature to below 300 degrees0C to avoid the formation of Dioxin/Furan toxins.

The gas flow after cooling down will be guided through the absorber, with ceramic gaskets inside. Thanks to the contact process between the gas phase and the liquid phase (NaOH solution), acid gas components such as HCl, HF, COX, SOx, NOx, Dust... will be removed from the exhaust before being discharged into the environment through a 20m high chimney. The absorption solution is recirculated and NaOH is added regularly to ensure the correct concentration for the treatment process.

Periodically, the solution will be discharged into the wastewater treatment system and replaced with new solution. The heat generated from the treatment process is used to dry waste and sludge to limit heat emission into the environment and save fuel for the treatment process.

Ash residue generated from the burning process will be solidified before being safely buried.

Technology description

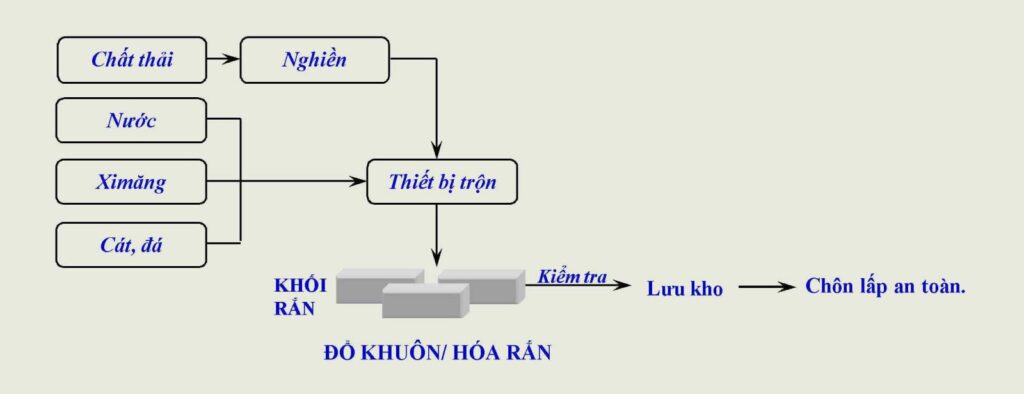

The waste that needs to be solidified is crushed to the appropriate size, then put into the mixer in batches. Additives such as cement, sand and polymer are added to perform the dry mixing process, then water is continued to perform the wet mixing process. The stirring process takes place so that the ingredients in the mixture mix evenly to form a homogeneous mixture. After the necessary mixing time, the mixture is put into cube molds. After 28 days of curing the solid block, the curing process takes place, causing the contaminated components to be completely isolated.

The solid block will be tested for compressive strength, leakage ability and carefully stored in warehouse, then transported to a safe landfill.

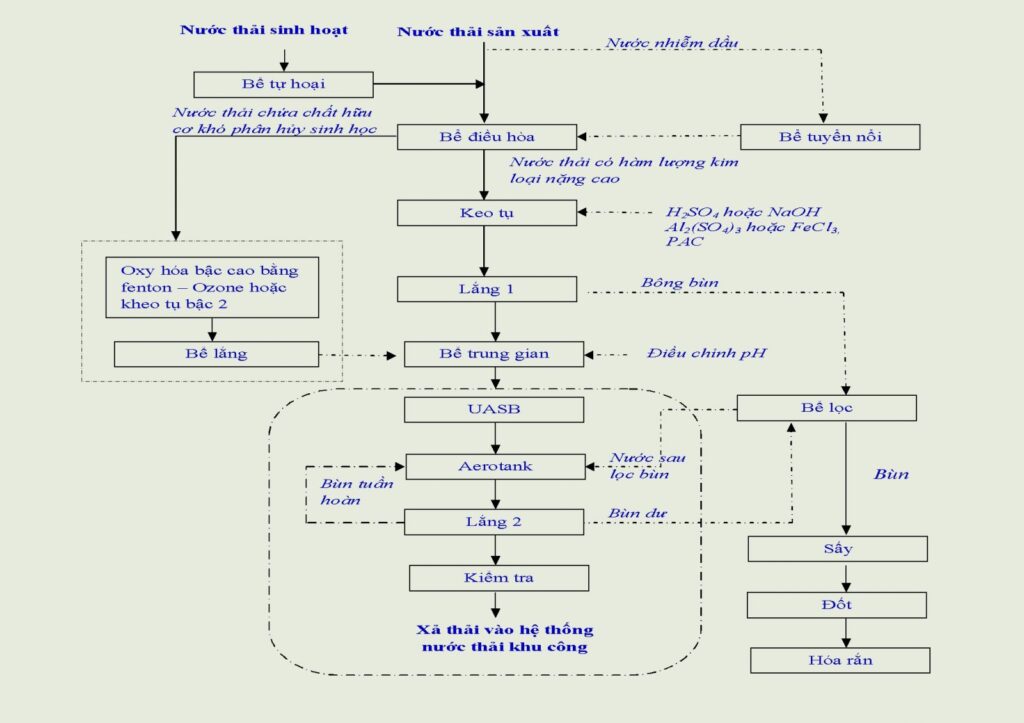

Technology description

Types of wastewater are classified and stored in separate containers for each type. This is a simple step but makes the processing in the following stages convenient, saves costs and optimizes processing technology, including the following types:

– Wastewater contains organic substances that are difficult to biodegrade;

– Wastewater contains high levels of heavy metals;

– Oil-contaminated wastewater.

The wastewater treatment system at the plant operates in batches. Each batch of wastewater will be alternately led into the equalization tank to stabilize the flow and concentration of wastewater before going through the next treatment stages. according to.

Particularly for oil-contaminated wastewater, the oil separation stage is performed by pressure flotation before passing through the regulation tank. Wastewater is treated in the wastewater treatment system according to the mentioned options. below:

– Mechanical treatment: sedimentation, filtration, phase separation and flotation.

– Physicochemical treatment: flocculation.

– Chemical treatment: high-level oxidation.

– Biological treatment: anaerobic (UASB), aerobic and anoxic nitrogen treatment in batch form with suspended aerobic activated sludge.

Technology description

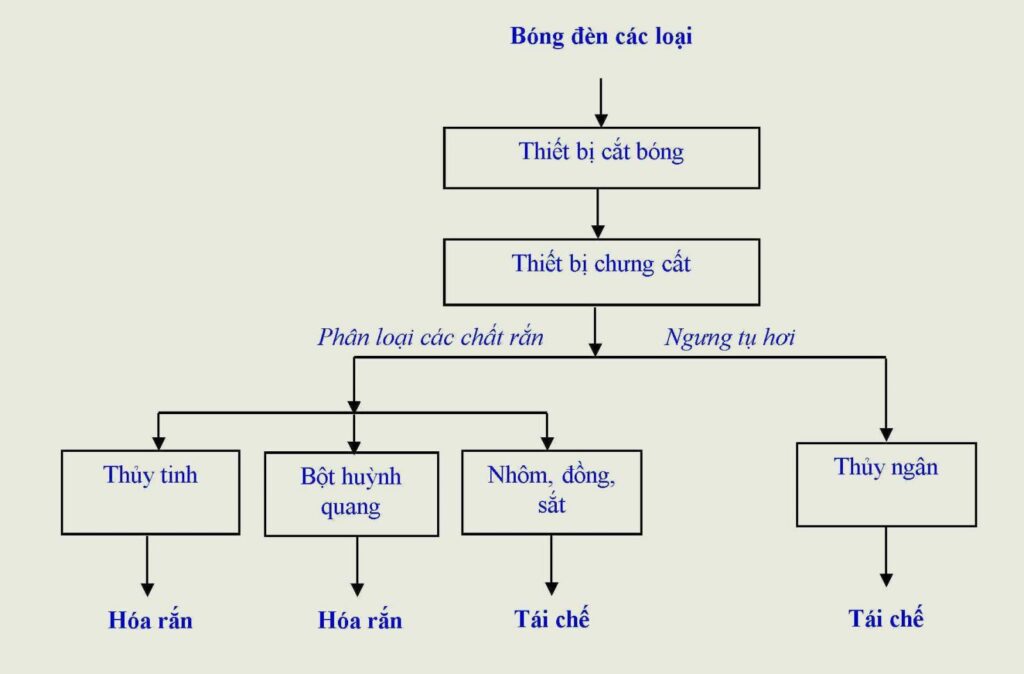

The process of treating waste fluorescent lamps is carried out in a closed treatment equipment including 3 stages: (1) bulb cutting; (2) distillation and (3) classification and recovery.

First, the bulb is put into a bulb cutting device to break the glass shell of the lamp to release substances in the lamp including fluorescent powder, Hg and inert gases. During the cutting process, mercury vapor is generated. into the activated carbon absorption system.

The mixture of glass, lamp head, filament and fluorescent powder is passed through a distillation apparatus at a temperature of 375oC to completely evaporate the amount of Hg absorbed in the mixture. All evaporated Hg continues to pass through the condenser to recover Hg.

The clean Hg-free mixture is passed through a sorting floor that separates the four components: glass, aluminum, copper, and fluorescent powder. Aluminum, copper and iron are recovered and recycled, while glass and fluorescent powder are continued to be solidified and buried safely.

For recyclable waste, VINAUSEN constantly researches to come up with the most effective recycling treatment plan, contributing to minimizing the impact of waste on the environment and bringing revenue to the company.